| Categories | Agricultural Equipment and Harvesting Machinery Manuals, New Holland Agricultural Equipment Manuals |

|---|---|

| Tags | New Holland VL610, New Holland VL620, New Holland VL630, New Holland VL640, New Holland VL660, New Holland VM460 |

| Download File |

|

| Document File Type | |

| Copyright | Attribution Non-commercial |

NEW VM, VL New Holland High Capacity Multifunctional Grape Harvesters Models VM460, VL610, VL620, VL630, VL640 and VL660 Technical innovation 2003. Gold medal for VM/VL harvesting head NEW VM, VL Technological innovations A great team of specialists with 30 years of experience, developed and build more than 10,400 grape harvesters that operate all over the world. They carry the spirit of New Holland, the brand that continues to confirm its leadership in mechanised harvesting systems.

Agricultural Equipment Manual Free Download. Lawn Mowers Specs. Power Harvesting Machinery Specification Download PDF.

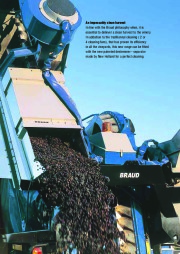

The introduction of a range of high capacity grape harvesters for medium and wide vines, profits from the Braud technology that has been acquired over the years. The product features that ensure excellent picking and remarkable cleaning quality associated to a multifunctional tractor base, answers today’s wine growers needs looking for the best quality. Superb harvest quality The new shaking system, which features the independence of each shaker, combines the possibility for high capacity and quality of harvest. The new arrangement of the shaker fixation will further enhance these important advantages. The new patented shaker fixation offers maximum suppleness and flexibility to the shaker system. Adaptation of the number of active shakers and their position, according to the height of the grapes on the vines, is made quick and easy. This will allow everybody to work with ideal shaker settings in any vineyard at maximum performance with full respect of the harvest. from the specialist. A comfortable environment The new cab of the VM and VL models is designed to provide maximum comfort. A comfortable operator concentrates on the job in hand and performs better over a longer period of time. Highly visible instrumentation and ideally located controls provide the latest in operator convenience. New multifunction On the VM and VL models a new system has been introduced to quickly have the base unit available for usage other than harvesting. This patented system allows detachment of the harvesting head in less than 15 minutes by one operator without using any tools. An extendible front equipment arm is optionally available. This fully adjustable interface is operated from within the cab where its controls are integrated into the multifunction lever. from the specialist. An impeccably clean harvest In line with the Braud philosophy when, it is essential to deliever a clean harvest to the winery. In addaition to the traditionnal cleaning ( 2 or 4 cleaning fans), that has proven its efficiency in all the vineyards, this new range can be fitted with the new patented destemmer – separator made by New Holland for a perfect cleaning. NEW VM, VL Models VM and VL Extended comfort and full control The operator’s contribution to the increasing quality of grape harvesting is vital. The platform is designed for total operator’s control with a multifunction lever that centralises all main functions for harvesting or other work in the vineyard. The cab versions are standard equipped with heating and air-conditioning. They are perfectly sealed and pressurised, which is an important advantage for the use of the machine all year long. A new multifunction lever An ergonomic electrical lever, fitted on the armrest, controls the motion, the setting functions of the picking head It controls the hight and the levelling. All the multifunction attachements are controlled from the same lever by by choosing one of the 8 pre-set programms. L. A perfect blend for top quality ha arvesting and full multifunction. Quick horizontal shaking rods spacing Varying leaf volumes of the vine, picking conditions and grape varieties require to adapt the horizontal distance between the shaking rods. On his monitor the operator controls the shaking rods spacing. Because of this integrated and easy to use feature, the setting is carried out so quickly that the respect of thevines is ensured in any vineyard and vegetation shape.